What is the function?

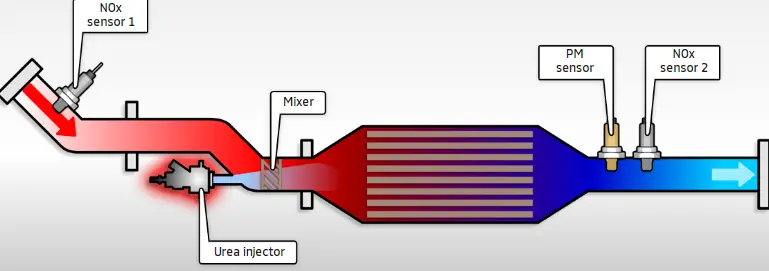

When the actual integrated value of the NOx purification calculated from the exhaust silencer NOx sensor No. 1, No. 2 input becomes lower than the integrated value estimated from the catalyst temperature, exhaust air temperature, and AdBlueTM injection quantity, this monitor determines that the SCR’s purification efficiency has decreased. When the DCU deems the SCR’s purification effectiveness reduced, it assigns diagnosis code P20EE. When the fault code clears and after 25-30 minutes of driving cycle the fault comes back probably you are not happy.

Possible problems.

-Dilution or deterioration of the AdBlue

-Failed diesel fuel system

-Failed No. 3 exhaust gas temperature sensor (DPF temperature)

-Failed urea injector assembly injection quantity is small

-Failed urea pump integrated with a supply pump

-Failed exhaust centre pipe integrated with SCR

-Failed No. 1 exhaust NOx sensor

-Failed No. 2 exhaust NOx sensor

What conditions do we check?

-After the exhaust muffler NOx sensor No. 1, No. 2 heater is activated.

-During urea injection assembly.

-During on-line dosing.

-Not during DPF regeneration.

-Barometric pressure is more than 750 hPa.

-Intake air temperature is more than -12°C.

-The ammonia is adsorbed onto the SCR sufficiently.

-The SCR efficiency is 0.7 or more.

Where do we start?

Always check for other fault codes and read the data list, if you find another fault like the oil level being too high some help is here: Mitsubishi L200 oil level is too high reset P252F DPF on.

More help with how the dpf system works is here: Mitsubishi L200 DPF System How Is work?

-First, check the exhaust gas temperature sensors (DPF temperature) all 3 sensors’ temperatures are close to each other, if 1 is too far is possible fault code, needs to be replaced.

-Check any other diagnosis code related to the exhaust muffler NOx sensor No. 1, No. 2, urea injector assembly and urea pump (supply pump) is set.

-Check the AdBlue injector resistance between terminals. Measure the resistance between the urea injector body and either terminal No. 1 or terminal No. 2 of the connector at the urea injector assembly (check short to earth in the internal circuit of the urea injector). Standard value: 11.4 to 12.6 Ω (at 20°C) If the resistance deviates from the standard value, replace the urea injector assembly.

-Pressure check for urea system: Warm up the engine until data list item No.15: Supply pump power stage status is ON. Check the data list item No. 6: SCR substate machine and item No. 9: Modeled urea pressure. Standard value: SCR substate machine reaches Metering control, and Modeled urea pressure reaches “5,000 to 6,500 hPa”.

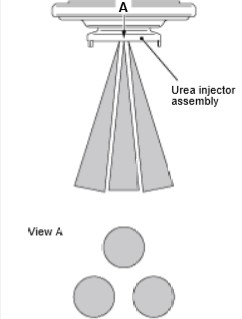

-Check the AdBlue injector condition and inlet hole to make sure is clear we can see on the picture how is blocked.

Check the spray pattern, Remove the urea injector assembly from the catalytic converter without disconnecting the urea injector assembly connector and the urea line tube A from the urea injector assembly and start self-check, is in DCU menu, select Special Function and self check It takes approximately 30 seconds until the AdBlue is injected from the urea injector assembly after the urea pumping and injection test is performed because it takes time until the urea line tube is filled with the AdBlue we can see on the picture is the correct spray patter.

– Carry out a check visually of the SCR catalyst if the damage needs to be replaced and if we remove the heave point to clean it with special fluid or just give it to a professional person.

-Carry out the ammonia purge to consume ammonia adsorbed onto the SCR, Start the engine and run at idle-select from the main menu Engine-Special Function-Ammonia purge-Carry out Item No. 56: Ammonia purge, The idle speed increases while ammonia purge is in progress (approximately 2,200 r/min).

Return to System select-DCU, select Special Function-Ammonia purge-Carry out the No. 1: Stop Urea injection from Ammonia purge, Do not disconnect the diagnosis connector during the ammonia purge. When the ammonia purge is completed, the value of the data list item No. 76: Estimated ammonia load decreases and smaller value is set.

Confirm that the idle operation returns to the normal engine speed, and then turn the ignition switch to the LOCK – OFF position. When 30 minutes pass after the ammonia purge is performed, the engine speed returns to the normal idle operation.

0 Comments